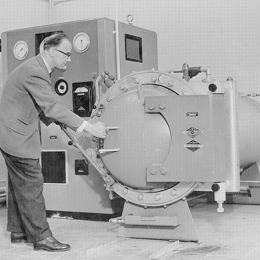

We design and build industry leading CORROSION testing Autoclaves

Easy to set-up. Safe to use. Flexible to suit your space. Our autoclaves makes reliable testing easy, so you can focus on processing great results.

Do you have an autoclave related question? Then speak to one of our autoclave experts by clicking the link below.

145

Years

Continued

Innovation

500+

Autoclaves

“LBBC Baskerville have quickly become our go-to autoclave partner. The process of working with them is easy and efficient, and they have great attention to detail. Their autoclaves are easy to use, saving us hassle in the lab, so we can focus on testing.”

Some challenges associated with autoclave corrosion testing

Autoclave testing is crucial to understanding how corrosion impacts materials and equipment performance in a wide range of applications. However, testing can be a challenging process:

Hard to Use

Inconsistent Operation

Contamination

Safety Issue

LBBC Baskerville autoclaves have been carefully designed to ensure they are:

Easy

Running a test couldn’t be easier. Your autoclave will be hassle free allowing you to stay focused on what matters.. your excellent data!

Safe

We take care of safety and compliance for you. You can run a test in confidence with the reassurance that you have our full support.

Reliable

Producing great, reliable data is the reason LBBC Baskerville exists. We ensure that your autoclave will suit your application and provide support to ensure it operates as expected.

What do you get through partnering with us?

1 Increase Productivity

2 Ensure Safe Operation

3 Improve your data

How to work with us

1. Book a

Call

2. Agree Autoclave Specification

We prepare an autoclave proposal that suits your needs and discuss this with you.

3. Start

Testing

Begin producing reliable results easily and safely with confidence in your tests.

4. Ongoing

Support

We are here to keep your autoclave running efficiently and effectively.

Test your Autoclave skills

-

It takes just 2 minutes

-

It’s completely free

-

Receive customised results instantly

Let’s chat

Whether you’re buying, repairing or just need some help, whatever it is, book a free call or fill in our autoclave enquiry form and one of our autoclave experts will get back to you today if possible.

Stay in the loop. Sign up to get testing tips, guides, ideas and updates.

Latest News

6th generation Pickard joins LBBC Group fo…

Our Partners